| |

A

cylinder is a device that converts fluid power into linear mechanical

force and motion. A hydraulic cylinder is a linear actuator used

for converting fluid energy to an output force in a liner direction

for performing various jobs. These include: Pulling or pushing

in engineering applications such as in machine tools, earth moving

equipment, construction equipment and space application.

The

hydraulic cylinder are used for all fields of engineering that

comprise of : earth moving, mining industry, construction machinery,

plant engineering, defence technology, automotive engineering,

mechanical engineering, textile industries, railways, power plants,

agricultural machinery etc. |

Features |

Advantages |

Benefits |

| Needs

and caps. |

Square,

precision-machined steel. |

Assures

concentricity of tube, bearing, cushion and piston rod. |

| Cylinder

tube. |

Cold

drawn seamless tube precision honed in to 0.4 microns and hard chrome

plated to 20-25 microns. Thicker walled tube than traditional low

pressure cylinders. |

Reduces

wear on piston seals and tube i.d surface thicker wall provides

Additional protection From leaks due to High pressure spikes. Hard

corrosion resistance and minimizes tube Scoring. |

| Piston |

One-

piece steel piston threaded onto piston rod, A dupont- wear guide

and teflon seal is located around the piston also. |

Prevents

oil leakage and scoring of cylinder tube ID. Anchored onto piston

rod with minimum under cut providing maximum strength. |

| Tie

rods |

Cold

drawn medium

Carbon steel with rolled threads at each end |

Provides

maximum strength for connecting cylinder mounts. Lock nuts prevent

loosening in service. Accurate torquing prevents leaks at tube seals. |

| Rod

seals |

Pre

loaded polyurethane seal is positioned in a groove in the back end

of the bearing cartridge ID. |

Pre-loaded

seal provides positive. Static and dynamic sealing of piston rod

at both high and low pressure. |

| Rod

wiper |

Sharp

double lip pre-lubricated, nitrile seal provides additional sealing

beyond rod seal.Additional material can be used to combat various

application demands, such as high heat.serve external conditions

could require the addition of a metallic rod scraper installed a

head of the rod wiper to effectively provide dual protection from

the elements. |

Prevents

dust, dirt & grit from entering the bearing cartridge and cylinder,

which significantly extend as the cylinder life |

| Ports |

Optional

ports sizes include flange ports, metric ports & over sized

ports. |

Universally

adaptale to any hose or fitting. |

| Piston

seals |

Symmetrical,

pre-loaded teflon, or polyurethane seal, wear quide are standard

are also available as an option |

Pre-loaded

seal prevents oil leakage at low prevent leakage & probability

of real failure during high shock operating conditions. |

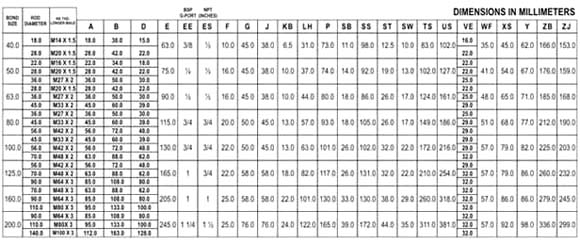

| FOOT

SIDE LUG |

|

|

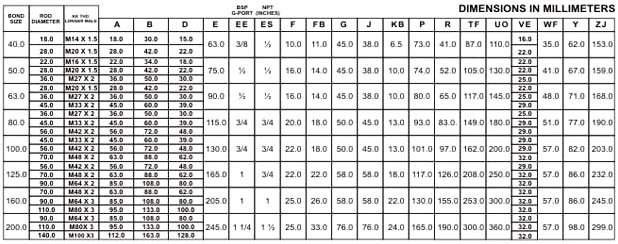

| METRIC

HIGH PRESSURE HYDRAULIC CYLINDER WORKING PRESSURE - 210 BAR ( 3000

PSI ) |

|

|

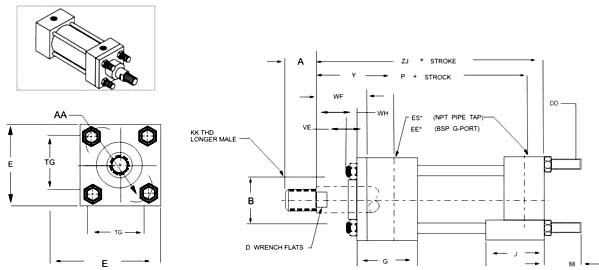

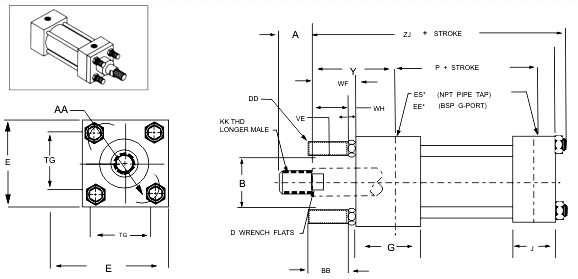

| TIE

ROD EXTEND CAP END |

| METRIC

HYDRAULIC CYLINDER WORKING PRESSURE - 210 BAR ( 3000 PSI ) |

|

|

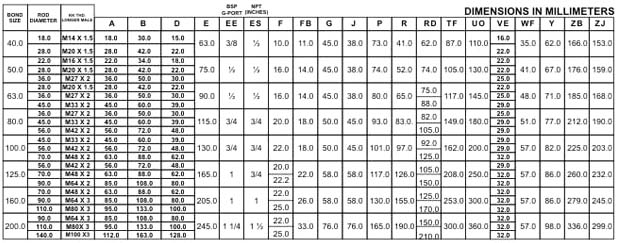

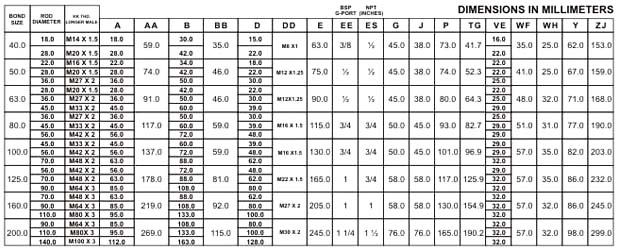

| HEAD

RECTANGULAR BLOCK FLANGE |

| METRIC

HIGH PRESSURE HYDRAULIC CYLINDER WORKING PRESSURE - 210 BAR ( 3000

PSI ) |

|

|

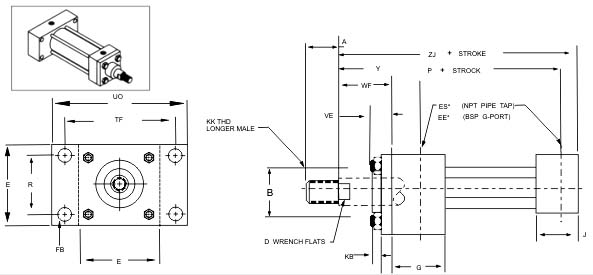

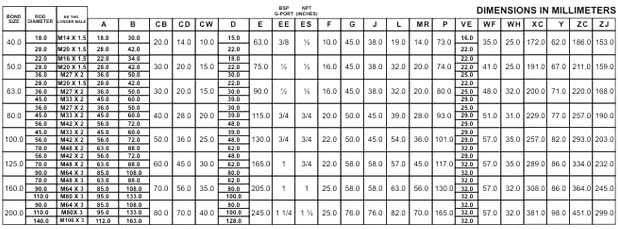

| CAP

RECTANGULAR BLOCK FLANGE |

| METRIC

HIGH PRESSURE HYDRAULIC CYLINDER WORKING PRESSURE - 210 BAR ( 3000

PSI ) |

|

|

| TIE

ROD EXTEND HEAD END |

| METRIC

HYDRAULIC CYLINDER WORKING PRESSURE - 210 BAR ( 3000 PSI ) |

|

|

| FIXED

REAR CLEVIS |

| METRIC

HYDRAULIC CYLINDER WORKING PRESSURE - 210 BAR ( 3000 PSI ) |

|

|